If you’re looking for an option for your commercial roof, you may have heard about TPO and EPDM roofing. Both TPO roofing and EPDM roofing are excellent, durable, and affordable options for commercial roofing. Not only are they easy and fast to install, but they’re also simple to maintain and extremely resilient. That being said, TPO roofing and EPDM roofing may have some significant differences worth noting. Let’s take a look.

If you’re looking for an option for your commercial roof, you may have heard about TPO and EPDM roofing. Both TPO roofing and EPDM roofing are excellent, durable, and affordable options for commercial roofing. Not only are they easy and fast to install, but they’re also simple to maintain and extremely resilient. That being said, TPO roofing and EPDM roofing may have some significant differences worth noting. Let’s take a look.

TPO Roofing Basics

Definition

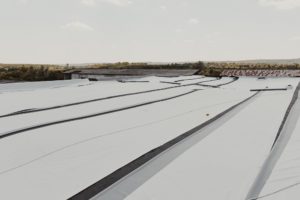

TPO is short for “thermoplastic polyolefin.” It’s a flexible, single-ply roofing membrane that will cover a flat or low-sloped roof. It tends to have a lower upfront cost. TPO’s white surface reflects UV rays, keeping energy costs low and protecting the roof. It holds up well to puncturing as well.

Installation & Repairs

Installation is quick. TPO comes in wide, large sections, which cover large areas quickly. These large sections get rolled out onto a roof and are attached with screws or adhesive. Then – and here’s the key – sections of membrane are heat-welded together. These heat welds are likely the most important step in TPO installation. They are what create a water-tight seal and protect the roof. The heat-welding is done with a machine, but you need a skilled installer to ensure the temperature is precise and the welds are strong.

TPO can usually be installed over existing roofing, as long as the substrate is clean and insulation boards are placed down.

Repairs are easy. When a part of the roofing material is failing, the roofing crew can replace just that area. The welds will make the roof water-tight once again.

Lifespan

Many TPO systems manufacturers put the lifespan of TPO at 15-20 years when properly maintained.

EPDM Roofing Basics

Definition

EPDM is short for “ethylene propylene diene monomer.” It is described as having a material more like a rubber innertube. It, too, is a flexible membrane that will cover a flat or low-sloped roof. EPDM roofing has a slightly higher upfront cost. It’s most often black in color, which tends to absorb sunshine energy. (Note – it can be white but is most often black.) It doesn’t handle puncturing quite as well as TPO but is very flexible, so it’s better at handling impact from larger items like hail.

Installation & Repairs

Installation is quick. EPDM also comes in large sheets, which means it can be installed quickly. A strong adhesive is used to fuse EPDM to the substrate, and EPDM can sometimes be used over existing roofing materials. The seams here are also what need to be properly installed, as this is where EPDM roofing tends to fail. With regular maintenance, this is no problem, but expect to pay attention to these seams.

Lifespan

Many EPDM manufacturers put the lifespan of EPDM at 20-25 years and sometimes much longer when properly maintained.

What’s Right for You?

These are the basics for EPDM and TPO. Most commercial businesses have EPDM roofs if they have flat or low-sloped roofs, but TPO has rapidly been catching up within the last two decades. TPO and EPDM are relatively similar. Besides the color, the average person might not be able to tell the difference between them.

Both of them are proven materials used successfully for a long time. Ultimately, the best choice of roofing for you will depend on your roofing needs, the environment the roof is in, and your budget. It may also depend on how long you want your roof to last and how frequently you want to maintain it.

Not sure whether your commercial roof needs TPO, EPDM, or something else entirely? Ask the experts. The best way to find out the options for you is to connect with the professionals. Contact Bert Roofing today to find out more. Find us online or call us at 217-307-8142.